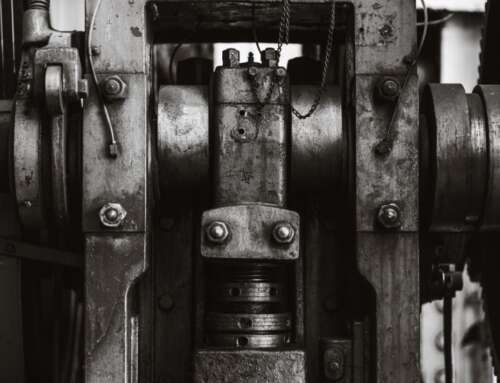

Bearings play a vital role in the movement of your machines. Bearings help to support the weight of the load, helping parts move without too much friction. Since your bearings are so important to the overall well-being of your machinery and its motion, you want to ensure that you properly maintain them. Putting together a maintenance plan is one of the best ways to ensure you maintain your bearings. Here are five bearing maintenance tips that will help to extend the life of your bearings, and thus, help your machinery to operate efficiently and effectively.

Check the Bearing Housing and Shaft Before Mounting

The first step to proper maintenance of bearings is to always check the bearing housing and shaft before mounting. As you inspect the bearing, you should be looking for nicks, scratches, dings or other imperfections. Minor nicks or scratches may be able to be wiped clean. However, large dings or dents in your bearings may indicate that the bearing is damaged and should not be used. If your bearings are damaged often, your machinery may need a repair.

Mount the Bearings Correctly

Anytime you are mounting bearings in your machinery, you need to ensure you are mounting the bearings correctly. If you are not sure how to mount your bearings, hire a pro, such as a bearing specialist. If you use the incorrect method for mounting the type of bearings you have, you can damage your bearings as well as possibly damaging the machinery.

Avoid Overheating Your Bearings

Your bearings are made from steel. If the bearings are heated above their temperature limit, they can start to soften and become deformed. This reduces the amount of carrying capacity for the bearing and can permanently damage them. Always learn what the heat range is for your bearings and ensure you do not overheat them.

Ensure You Properly Lubricate Your Bearings

One of the most common reasons why bearings fail prematurely is that they are not properly lubricated. Using the wrong lubrication, using too much lubrication or using too little can all negatively affect your bearings. A bearing specialist can work with you to help you learn what the right lubrication for your bearings is, and how much you should be using, based on your environmental factors and the type of equipment you are using.

Implement a Proactive Maintenance Schedule

The final tip that can help you with bearing maintenance is to implement a proactive bearing maintenance schedule. Being proactive helps you to catch minor problems before they turn into much larger ones. This can help extend the life of your bearings, but possibly also helps extend the life of your machinery.

Bulk Delivery of Bearing Lubricants at Your Door

Your bearings help your machinery to function as they should. If your bearings are damaged, or not property lubricated, your machinery can suffer or not operate at all. Here at Inventory Express, we sell many industrial lubricants and bulk oil that you need to properly lubricate your bearings and more. Contact us today to speak to a representative about your bulk delivery needs.