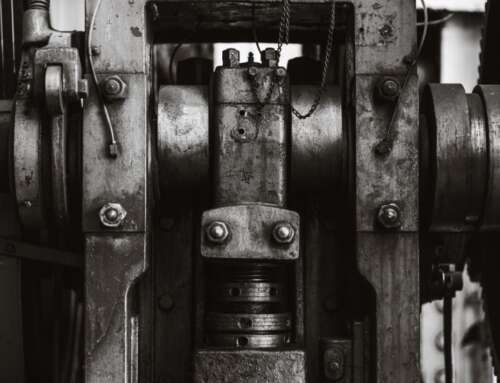

Ever wondered why gears sometimes fail, causing disruptions in mechanical systems? From inadequate lubrication to material flaws, a variety of factors can contribute to gear failures. In this guide, we explore the common reasons behind gear failures, methods for determining their causes, and strategies for enhancing equipment efficiency through proactive maintenance practices.

What Causes Gear Failures?

Gear plays a crucial role in mechanical systems, yet they are prone to failure for various reasons. Inadequate lubrication, material flaws, incorrect loading, misalignment, and operational mistakes are some of the common causes of gear failure. Every time there is gear failure, it leaves distinct signs on the equipment. By accurately interpreting these indicators, maintenance staff can effectively pinpoint the root cause of the issue that guides them towards the most appropriate course of action for repair and prevention.

How to Determine the Cause of Gear Failures

Recognizing the root cause of gear failure is a crucial first step in troubleshooting. Let’s explore some effective methods for identifying the cause of gear failure.:

Run Tests

The initial step in diagnosing gear malfunctions involves thorough testing. A crucial aspect of this process is oil analysis, which offers insights into the internal mechanisms of gear systems. Analytical ferrography and elemental analysis are key tests used to identify the types of wear and the presence of impurities. These tests are instrumental in uncovering the root causes of gear degradation.

Gather Information About Processing History

Examining the equipment’s operational history in detail is crucial. Variations in lubricants, operating conditions, or maintenance schedules can greatly affect how well a gear works. Having access to this historical information can help us understand why the failure occurred. It allows us to spot any patterns or changes that might be linked to the problems.

Check for Wear Damage

Examining the equipment visually is important. Various types of wear, such as adhesion, fatigue, and abrasive wear, are associated with diverse properties. For example, adhesive wear may show signs of material transfer between surfaces, while abrasive wear might manifest as scratches or grooves. To identify the underlying causes of gear failure, it is crucial to recognize these patterns.

Review Equipment Maintenance Procedures

Maintenance procedures greatly influence the longevity of gears. Many common causes of gear failure can be prevented by diligently following the prescribed maintenance protocols. This includes following lubrication schedules, conducting regular inspections, and storing lubricants correctly. Failure to comply with these standard procedures can lead to premature wear.

Enhancing Equipment Efficiency

By understanding the root causes of gear failures businesses can proactively address issues, minimize downtime, and extend the longevity of their gear systems.

Inventory Express is committed to supporting businesses in their efforts to maintain optimal performance and reliability in machinery by supplying the optimal lubrication products to maintain your important machinery. Prevent gear failures and downtime. Contact us to schedule a recurring delivery of bulk lubricants for your equipment maintenance programs.