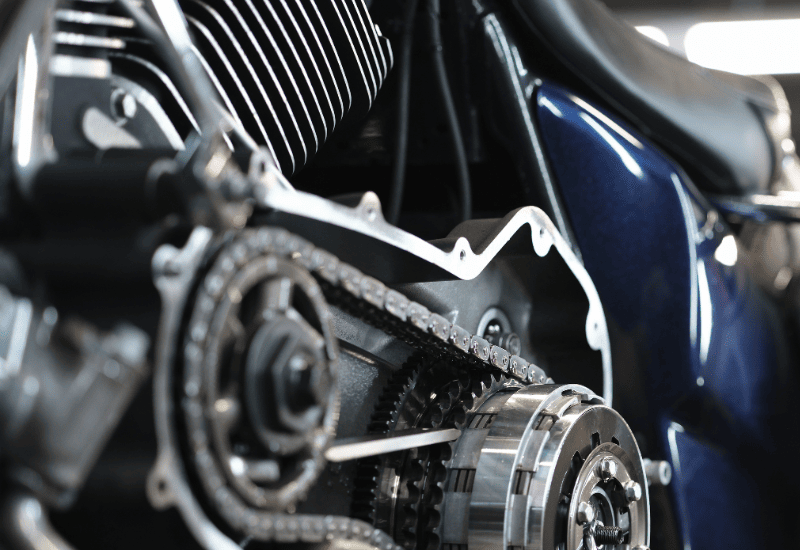

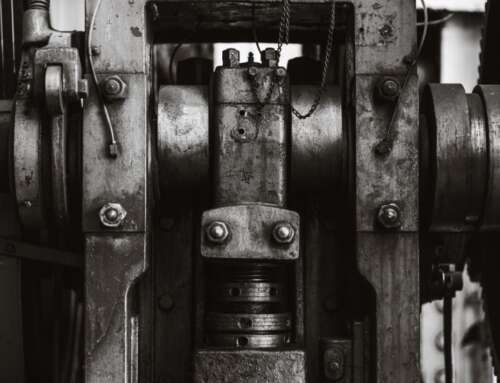

Gearbox oil checks are essential for industrial machinery maintenance due to their precision and dependability. This activity cannot be overstated because it directly impacts the longevity and performance of these expensive assets. The following guide will spotlight gearbox oil monitoring and demonstrate how predictive maintenance technology helps prevent expensive machinery issues.

Why Monitor the Condition of Gearbox Oil?

Gearbox oil is essential to industrial machinery. It lubricates, transmits heat, lessens friction, and stops wear. Ignoring this essential fluid could result in expensive repairs and unplanned downtime.

Key Factors to Monitor Gearbox Oil Condition:

Viscosity

Viscosity is an important consideration when choosing gearbox oil. It measures the oil’s thickness or flow resistance.

Viscosity monitoring allows you to see odd viscosity variations that could indicate contamination or deteriorating oil. High viscosity can increase friction, whereas low viscosity may lead to insufficient lubrication.

Demulsibility

Demulsibility is a critical factor that measures the oil’s ability to separate from water, ensuring efficient lubrication in gearbox applications.

Ferrous Density

The ferrous density of an oil can be used to determine how much iron is present in it. Wear and tear on the gearbox may be indicated by an elevated ferrous density. Measurements of ferrous density can identify signs of corrosion early on, shielding the gear from harm and prolonging its life.

Water

Corrosion, weakened film strength, and lower lubrication effectiveness can result from the presence of water in gearbox oil. You can have good corrosion control and preserve the integrity of your machinery by routinely monitoring for water content.

Oxidation

Gearbox oil loses wear and friction protection due to oxidation. Monitoring oxidation levels helps you plan oil changes and maintain performance.

Total Acid Number (TAN)

This measures oil acidity. High TAN values indicate acid content, which accelerates oil deterioration and gearbox corrosion. Frequent TAN analysis helps identify issues early.

How to Monitor the Gearbox Oil Condition

Gearbox oil monitoring is not a fixed solution. There are multiple methods and tests that are used to verify thoroughness. Some tests include:

- Particle Count: An examination of the oil’s particle count offers information about its purity. Elevated particle counts suggest the presence of wear debris and pollutants. Oil cleanliness can be preserved by putting filtering and purifying procedures into place.

- Elemental Spectroscopy: This examination examines oil chemistry. Iron, copper, and aluminum from gearbox components can be detected. Maintenance can be guided by early metal detection.

- Wear Debris Analysis (WDA): This specialized method looks at wear particles in the oil. It assists in determining the kind and cause of wear, enabling focused maintenance. WDA is especially helpful in anticipating upcoming gearbox breakdowns.

Industrial machinery is continually evolving, making predictive maintenance technology essential. Data analytics and cutting-edge monitoring solutions can help prevent issues and extend equipment life. Viscosity, ferrous density, water content, oxidation, TAN, particle count, elemental spectroscopy, and wear debris analysis are just a few characteristics that can be tracked in real time or through planned inspections thanks to predictive maintenance technology.

Count on Inventory Express for Quality Oils & Lubricants

Industrial machinery performance and health depend on proactive gearbox oil condition monitoring. Regularly evaluating viscosity, ferrous density, water content, oxidation, TAN, particle count, elemental spectroscopy, and wear debris analysis helps prevent costly equipment issues and downtime. Inventory Express has the tools and expertise to keep your machinery running smoothly. To learn more, contact us.