Choosing the right gearbox oil is crucial for maintaining the efficiency and longevity of your machinery, but navigating through all the available options can be overwhelming. Additionally, selecting the right gearbox oil is not just a matter of preference, it directly affects the productivity and lifespan of your industrial equipment. This guide will provide you with expert guidelines and essential tips to help you make informed decisions when selecting your gearbox oil.

Selecting the Right Gear Oil

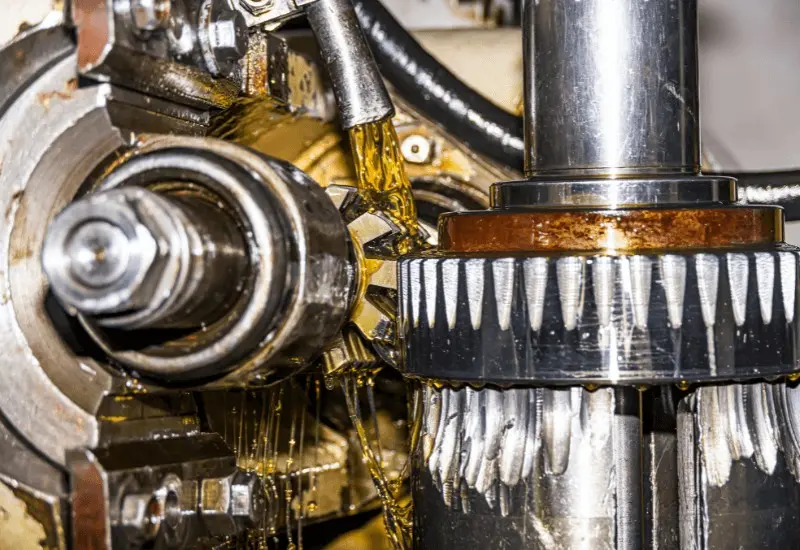

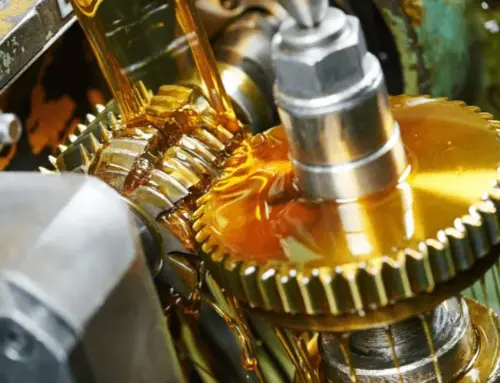

The first step in choosing the right gear oil is understanding the specific needs of your gearbox. Gearboxes need lubricants that can withstand various loads, temperatures, and environmental conditions. The type of oil used significantly impacts the system’s health, energy consumption, protection against wear and tear, and overall operating efficiency.

When talking about gear oil, it is essential to consider these factors. The quality of the lubricant depends on the type of base oil used. It could be either mineral or synthetic. Synthetic lubricants cost more than mineral oils but last longer and perform better in high temperatures. Your budget and the conditions in which your machinery operates will determine which is the best base oil for you.

The choice you make between mineral and synthetic oils also impacts how much maintenance is needed and how often you must change the oil. Synthetic oils usually allow longer intervals between replacements. Therefore, to create an optimal and cost-effective lubrication plan, it is essential to carefully weigh the operational requirements against the associated costs.

What to Consider When Selecting Gearbox Oil?

Viscosity of the Gear Box Oil

The oil’s viscosity needs to strike a balance to ensure optimal performance in the gearbox. It should be high enough to create a protective film, but also low enough to allow gearbox movement and heat distribution. The viscosity, or thickness, of oil changes with temperature, and this change is measured and described by a value known as the viscosity index. Viscosity index indicates how well the viscosity of an oil remains stable across different temperatures. A higher viscosity index indicates that the oil’s viscosity changes less with temperature variation and a lower viscosity index indicates that the oil’s viscosity changes significantly with temperature.

Additive Package in the Oil

The type of additive package used in the lubricant will determine the lubricant’s overall category and significantly influences its performance in different operating conditions. These additives improve oil wear, oxidation, corrosion, and thermal stability. The choice of optimal additives depends on factors such as gearbox gears, operating temperatures, and climate conditions.

Oil’s Compatibility with the Gearbox’s Seals and Materials

Using the wrong gearbox oil can lead to premature wear, damage to seals, and corrosion of gearbox components. Due to this, the oil and gearbox may wear out faster and require more expensive maintenance. It is important to make sure that there is compatibility between the oil and gearbox. This will extend the gearbox’s lifespan and enhance the overall operational efficiency and financial viability of the machinery.

Trust Inventory Express for Quality Gear Oils

Choosing the correct gearbox oil is essential to ensure that your gear systems perform at their best. We highly recommend you check your owner’s manual to determine the recommended gear box oil for your application. From there, our team of experts can provide a recommendation for a product that will best enhance the performance of your gear systems. To place and order for gear oils or other lubrication products, contact us today.