Unexpected equipment failure leads to costly downtime, and insufficient or improper lubrication is a leading cause of preventable equipment failure. What’s more, these costs tend to fall outside budgetary planning, making the damage even more difficult to recover from.

Proper lubrication to prevent machinery failures is the number one way to maintain almost any heavy equipment. In the automotive world, regular oil changes are considered the most important part of regular maintenance and the same is true of heavy industrial equipment. Here, we will discuss the ways proper machinery lubrication can save you costly breakdowns.

The Importance of Using High-Quality Lubricants

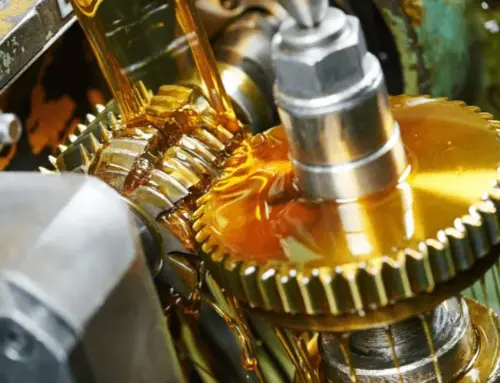

Adequate industrial lubrication reduces friction and heat and protects components with low mechanical tolerance from dirt and debris. Without lubrication, otherwise well-cared-for heavy equipment can break down in minutes. By using top-tier oils and lubricants, the operational life of your equipment will be prolonged significantly. But these are not the only benefits of lubrication maintenance.

Certain lubricants are made with special additives with additional benefits such as improved performance under extreme conditions, corrosion protection, and increased water resistance. This brings us to our first recommendation: Use high-quality lubricants specially formulated for your equipment and the task at hand.

Matching Machinery Lubrication Types to the Right Application

There are many types of machinery lubrication, each designed for a different purpose.

Mineral Oil Lubricants

The most common type of lubricant, mineral oil lubricants, is made from crude oil and is used in a wide variety of applications. These are the least expensive types of industrial lubricant.

Bio-Based Lubricants

Made from natural materials like animal fats and vegetable oils, bio-lubricants are usually used in ecologically sensitive applications.

Synthetic Lubricants

Synthetic lubricants tend to offer the highest performance profiles as they are highly resistant to extreme temperatures and other harsh operational conditions.

Specialty Lubricants

Specialty lubrication is used for highly specific applications where the properties of the lubricant are needed for specialized use. They are optimized for high temperatures, corrosive conditions, extreme pressures, and more.

Greases

These semi-solid lubricants are used in conditions where oil lubrication will not hold or otherwise be suitable. Greases are frequently seen on semi-truck trailer hitches and are prized for being resistant to washing or wiping away on exposed surfaces.

Common Lubricant Uses:

- Bearings and Gears

- Hydraulic Systems

- Wire Rope and Chains

- Valves and Actuators

- Heat Exchangers and Cooling Systems

To learn more and ensure you get the right machinery lubrication for your production needs, get in touch with the heavy equipment lubrication pros at Inventory Express today. We’ll deliver top-quality industrial lubricants to ensure your machinery runs smoothly.